As one of the essential elements of a roofing system, shingles serve as the first line of defense for homes against rain, wind, UV rays, etc. But do you know how shingles are made? This article will walk you through every step of the manufacturing process, starting with the raw materials and concluding with the final product on your roof.

What are shingles made of?

Roof shingle construction comprises a fiberglass base mat soaked in asphalt and mineral granules plastered on top. Different construction methods exist for shingles, but this article will concentrate on the most prevalent type, asphalt shingles. These include metal, wood, and slate. Each has a different construction approach.

The Shingle Manufacturing Process

1. Raw material preparation.

The process starts by gathering the main components:

· Fiberglass Mat – Acts as a base that adds strength and flexibility.

· Asphalt – Functions as the waterproofing agent.

· Mineral Granules – Adds color, UV protection, and durability.

· Fillers & Stabilizers – Aids the asphalt in attaching securely to the mat.

2. Fiberglass Mat Production

🔹 Creating the Shingle Base

Fiberglass We can produce mats by weaving together glass fibers into a sheet. We later roll out this “skeleton” or mat to undergo coating, which provides the shingle with structure and resilience.

3. Asphalt Coating

🔹 Waterproofing and Protection

Both sides of the fiberglass mat are coated with hot asphalt, which makes the shingle waterproof and gives it the ability to withstand extreme weather.

Quality Control Checkpoint

Before the next step, machines perform a quality control check to inspect the coated mat for consistency, structural integrity, and thickness.

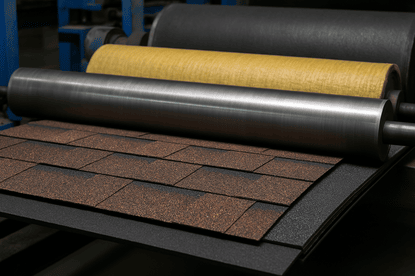

4. Granule Application

🔹 Adding Color and UV Resistance

Ceramic-coated mineral granules are embedded on top of the shingle while the asphalt is still warm and sticky. These granules provide additional protection from ultraviolet rays and come in different colors to enhance the shingle’s aesthetic appeal.

In humid regions, some shingles are also fortified with algae-resistant granules to reduce staining.

5. Sealing and cooling.

The mat passes through cooling rolls, and once cooled, a strip of heat-activated adhesive is applied, which helps the shingles stick to each other when installed on a roof.

6. Cutting and packaging.

After the sheet is turned into individual shingles, each shingle is inspected, stacked, and bundled for shipment. The bundles are also packaged, labeled, and shipped to suppliers or retailers.

Types of Asphalt Shingles

· 3-Tab Shingles – Traditional and cost-effective.

· Architectural Shingles – Thicker and more durable with a dimensional look.

· Luxury Shingles – High-end, mimicking wood shake or slate.

Understanding Shingle Quality: Why it Matters

Knowing the manufacturing processes for shingles can significantly inform your choice of roofing materials. Cheaper alternatives almost always come with a cost that isn’t immediately apparent. Shingles from good manufacturers tend to last, perform better, and offer greater protection, especially when backed by warranties from reputable manufacturers.

Need New Shingles? Trust Sunbelt Roofs.

If you’re based in Louisiana or Mississippi, contact Sunbelt Roofs for comprehensive advice or service regarding roof replacements or other shingle options.

📞 Louisiana: 985-805-6921

📞 Mississippi: 228-222-5255

Free estimates are available!

Final Thoughts

Homes offering long-lasting protection cover the entire country. That is the result of combining precision engineering (from fiberglass to finished shingles), smart design, and durable materials used in crafting roofing shingles.